Pipe Line Pigging in United Arab Emirates

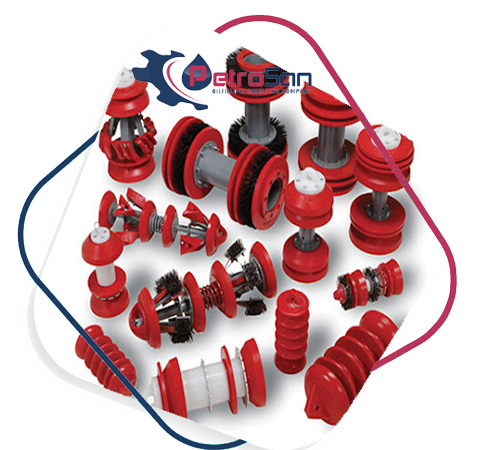

Manufacturer and suppliers of high quality pipeline pigs like Utility Pigs (foam, brush, mandrel, spherical, solid cast for cleaning/batching), Inspection Pigs (Smart Pigs with sensors for corrosion/cracks), and Gauging Pigs (checking pipe geometry) are the main categories of “pigs” (devices) used in Petrosan pipeline pigging. Each type of pig is intended for a particular task, such as removing debris, separating products, or evaluating pipeline integrity.

PetroSan Oilfield engineering is one of the to most certified with ISO 9001, 14001 and 45001 manufacturer and suppliers of high quality Utility Pigs (foam, brush, mandrel, spherical, solid cast for cleaning/batching), Inspection Pigs (Smart Pigs with sensors for corrosion/cracks), and Gauging Pigs (checking pipe geometry) in United Arab Emirates.

Utility Pigs (Cleaning & Maintenance)

- Foam Pigs: Basic, flexible pigs for debris/liquid removal, available in various densities (open/closed cell).

- Brush Pigs: Feature wire or plastic brushes for stubborn scale, rust, and deposits.

- Mandrel Pigs: Steel body with attached cups, discs, or brushes for sealing and scraping.

- Solid Cast Pigs: Molded polyurethane pigs with multiple seals, excellent for batching and high-pressure tasks.

- Spherical Pigs: Solid or hollow balls used for simple cleaning or separating products, good for tight bends.

Inspection Pigs (Smart Pigs)

- Ultrasonic Pigs (UT): Use ultrasonic testing to detect wall thickness loss and corrosion.

- Magnetic Flux Leakage Pigs (MFL): Detect metal loss and cracks using magnetic fields.

- Caliper Pigs: Measure the pipe’s internal diameter to find dents or deformations.

Other Types & Functions.

- Batching Pigs: Separate different products (e.g., different crude oils) in the same line to prevent mixing.

- Gauging Pigs: Check for obstructions or bore deformation before detailed inspection.

- Gel Pigs: Use gels for specialized cleaning, commissioning, or de-waxing.

- Product Recovery Pigs: Reclaim valuable product from the pipeline, common in food/sanitary industries.

Pipeline pigging is mainly classified based on the physical architecture of the “pig” (Pipeline Intervention Gadget) or the function it serves. These are the common types utilized in the utility, gas, and oil sectors as of 2026.

1. Functional Types.

These pigs are classified by the specific job they perform inside the pipeline:

- Utility Pigs: The most common variety used for routine maintenance.

- Cleaning Pigs: Equipped with brushes or scrapers to remove debris, wax, and scale.

- Sealing/Batching Pigs: Used to separate different fluids or “batches” within the same line, or to displace products during decommissioning.

- Inspection (Smart) Pigs: High-tech devices that use sensors to “see” the pipe’s interior.

- Magnetic Flux Leakage (MFL): Detects metal loss, corrosion, and pitting.

- Ultrasonic (UT): Measures wall thickness and detects cracks using sound waves.

- Gauging Pigs: Used after construction or repairs to check if the pipeline has any internal deformities, dents, or ovality.

- Specialty Pigs:

- Gel Pigs: Made of high-viscosity chemical compounds to pick up debris or separate fluids.

- Plugs: Used to temporarily seal off a section of a pipe for maintenance or repair while under pressure.

2. Physical Design Types.

Pigs are also identified by their materials and structural build:

- Foam Pigs (Polly-Pigs): Made of open-cell polyurethane foam. They are flexible, inexpensive, and excellent for navigating pipelines with complex bends.

- Mandrel Pigs: Modular designs with a central steel body (mandrel) to which various components like cups, discs, and brushes are attached.

- Solid Cast Pigs: Molded as a single piece, typically from polyurethane. These are often used for batching and small-diameter cleaning due to their cost-efficiency.

- Spherical Pigs: Inflatable or solid balls often used as sealing pigs in systems where mechanical pigs might get stuck.

1. Primary Engineering Standards.

Pipeline pigging systems must comply with established codes to ensure structural integrity and safety:

- ASME B31.4 (Liquids): Governs systems for crude oil, water, and slurries. It mandates a design factor (F) typically constant at 0.72.

- ASME B31.8 (Gas): Covers natural gas and hydrogen blends, requiring variable design factors (0.40 to 0.72) based on the “Class Location” or nearby human activity.

- API RP 1626: Provides industry best practices for the design and maintenance of pigging programs.

- ISO 15590-2: Specifically details requirements for pig traps, including the design of major and minor barrels.

2. Pig Technical Specifications.

When ordering or designing a pig, the following specifications are critical:

- Diameter & Wall Thickness: Standard pigs are available for pipelines from 4″ to 60″. Sealing discs/cups are typically oversized by 1/16″ to 1/8″ to maintain a seal.

- Material: Most sealing components are high-grade polyurethane (PU). Standard shelf life for PU items is two years if stored in dry, dark conditions.

- Navigability: Pigs must be specified to negotiate bends. Standard utility pigs handle 3D bends (radius = 3x diameter), but specialized articulated pigs are required for 1.5D bends.

- Operating Range: Specifications must include maximum temperature (often up to 65°C for standard PU), maximum pressure (up to 150 kg/cm²), and a minimum continuous run distance (typically 200–300 km).

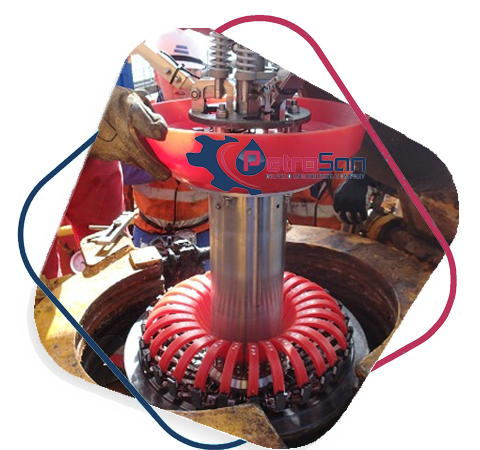

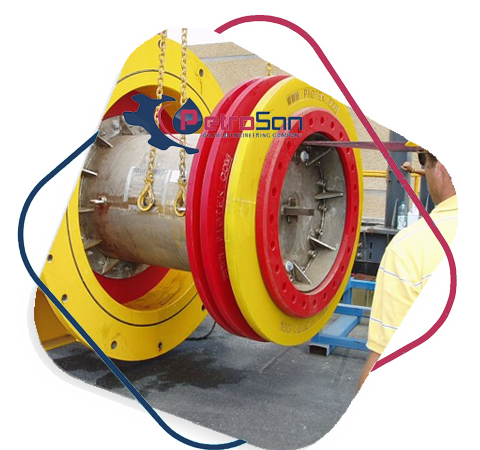

3. Pig Trap (Launcher/Receiver) Design.

A pigging station must meet specific geometry requirements to function effectively:

- Major Barrel: Must be oversized compared to the pipeline. For lines up to 20″, the barrel should be 2″ larger; for 20″ and above, it should be 4″ larger.

- Minor Barrel: Must match the pipeline’s internal diameter exactly to ensure the pig can exit or enter without getting stuck.

- Quick Opening Closures (QOC): Must include a safety interlock system to prevent opening while the barrel is under pressure, as per ASME Section VIII, Div 1.

- Kicker Line: The bypass line used to propel the pig should have a capacity of at least 25% of the main line flow.

PetroSan Oilfield engineering is ISO & PED certified manufacturer and suppliers of high quality Utility Pigs in United Arab Emirates, manufacturer of foam in United Arab Emirates, manufacturer of brush, manufacturer of mandrel in United Arab Emirates, manufacturer of spherical in United Arab Emirates, manufacturer of solid cast for cleaning/batching) in United Arab Emirates, manufacturer of Inspection Pigs (manufacturer of Smart Pigs with sensors for corrosion/cracks) in United Arab Emirates, and manufacturer of Gauging Pigs in United Arab Emirates (manufacturer of checking pipe geometry) in United Arab Emirates.

PetroSan Pipeline Pig Manufacturer and suppliers :

PetroSan Oilfield engg. co. is one of the leading Manufacturer and suppliers of Pipeline pigging in United Arab Emirates, Manufacturer and suppliers of Pipeline inspection gauge (PIG) in United Arab Emirates, Manufacturer and suppliers of pipeline foam pig in United Arab Emirates, Manufacturer and suppliers of pipe cleaning pigs in United Arab Emirates, Manufacturer and suppliers of Intelligent pigging (or smart pigging ) in United Arab Emirates, Manufacturer and suppliers of Caliper pig survey in United Arab Emirates, Manufacturer and suppliers of Foam pigs (or foam pigging ) in United Arab Emirates, Manufacturer and suppliers of Utility pigs for cleaning in United Arab Emirates, Manufacturer and suppliers of Gauging pig in United Arab Emirates, Manufacturer and suppliers of Gel pig technology in United Arab Emirates, Manufacturer and suppliers of Pipeline maintenance pigging in United Arab Emirates, Manufacturer and suppliers of Pipeline cleaning solutions in United Arab Emirates, Manufacturer and suppliers of Corrosion detection pipeline in United Arab Emirates, Manufacturer and suppliers of Metal loss inspection MFL (Magnetic Flux Leakage) in United Arab Emirates, Manufacturer and suppliers of Pipeline integrity assessment in United Arab Emirates, Manufacturer and suppliers of Pipeline flow assurance in United Arab Emirates, Manufacturer and suppliers of Pipeline commissioning pigging in United Arab Emirates, Manufacturer and suppliers of Pig launcher and receiver in United Arab Emirates, Manufacturer and suppliers of Pig trap in United Arab Emirates, Manufacturer and suppliers of Pig tracking equipment (or pig signaler ) in United Arab Emirates, Manufacturer and suppliers of Differential pressure pigging in United Arab Emirates, Manufacturer and suppliers of Pig velocity control in United Arab Emirates, Manufacturer and suppliers of Oil and gas pipeline pigging technology in United Arab Emirates, Manufacturer and suppliers of Submarine pipeline inspection in United Arab Emirates, Manufacturer and suppliers of API standard pipeline pigging in United Arab Emirates, Manufacturer and suppliers of Offshore pipeline pigging in United Arab Emirates, Manufacturer and suppliers of high density foam pig in United Arab Emirates, Manufacturer and suppliers of medium density foam pig in United Arab Emirates, Manufacturer and suppliers of low density foam pig in United Arab Emirates.

We Manufacture, Export and supply to many Countries as follows :

- ASIA – United Arab Emirates, China Thailand, Singapore, Sri Lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein.

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary, Belarus, Bulgaria, Slovakia, Moldova.

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands.

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See.

- South America – Argentina, Chile, Brazil, Colombia, Paraguay.

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger, Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena.

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara.

- Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland.

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.