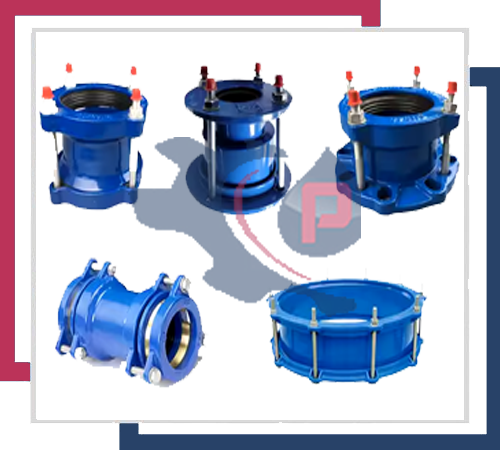

PetroSan Sleeve + Clamp

With a global industrial presence, PetroSan Oilfield Engineering Co. is a leading manufacturer of sleeve + clamp, including pipe repair split clamp, pipe repair sleeve split clamp, stainless steel pipe repair clamp, bell joint clamp, band strap leak repair clamp, pipe reinforcing sleeve, and pipe end mechanical coupling. All of your pipe projects can be supported by us. Oilfield goods for onshore and offshore projects, hydrocarbon processing, and fabrication and manufacturing services for oil and gas production and exploration wells are all supplied by our teams to the industry.

A Pipe Repair Split Clamp is a type of pipe fitting used to repair and reinforce damaged or leaking pipes. It is a split clamp that wraps around the pipe, allowing for easy installation without the need to disassemble the pipe.

A Pipe Repair Split Clamp typically consists of:

1. A split clamp body that wraps around the pipe

2. A gasket or sealant to create a tight seal

3. Bolts or screws to secure the clamp in place

Pipe Repair Split Clamps are used to:

1. Repair cracks, holes, and leaks in pipes

2. Reinforce weakened areas of pipe due to corrosion or mechanical damage

3. Connect dissimilar pipes or fittings

4. Provide additional support and stability to pipes

Benefits of Pipe Repair Split Clamps include:

1. Easy installation without pipe disassembly

2. Strong and durable repair solution

3. Resistant to corrosion and harsh environments

4. Can be used on various pipe sizes and types

5. Cost-effective solution compared to replacing the entire pipe

Clamp Materials :

Pipe clamp steel materials are typically made from high-strength, durable steel alloys that can withstand various environmental and operational conditions. Some common steel materials used for pipe clamps include:

1. Carbon Steel (CS): A popular choice for pipe clamps due to its high strength, weldability, and affordability.

ASTM A36, ASTM A572, ASTM A588, ASTM A105, ASTM A106, API 5L, ASTM A515, ASTM A516, ASTM A537

2. Stainless Steel (SS): Offers excellent corrosion resistance, making it ideal for applications in harsh environments.

ASTM A240 Grade 304, ASTM A240 Grade 316, ASTM A240 Grade 321, ASTM A240 Grade 347, ASTM A240 Grade 410, ASTM A240 Grade 440

3. Alloy Steel: A high-strength, low-alloy steel that provides excellent mechanical properties and resistance to corrosion.

ASTM A182 Grade F1, ASTM A182 Grade F5, ASTM A182 Grade F9, ASTM A335 Grade P1, ASTM A335 Grade P5, ASTM A335 Grade P9, ASTM A335 Grade P11, ASTM A335 Grade P22, ASTM A335 Grade P91, ASTM A691 Grade 1/2/3

4. High-Yield Strength Steel (HY): Designed for high-pressure applications, HY steel pipe clamps offer exceptional strength and durability.

ASTM A572 Grade 50, ASTM A572 Grade 60, ASTM A572 Grade 65, ASTM A588 Grade A, ASTM A709 Grade 50, ASTM A709 Grade 50W, API 5L Grade X52, API 5L Grade X60, API 5L Grade X65, API 5L Grade X70

5. Duplex Steel: A combination of stainless steel and carbon steel, offering excellent corrosion resistance and high strength.

ASTM A182 Grade F51, ASTM A182 Grade F53, ASTM A182 Grade F55, ASTM A240 Grade 2205, ASTM A240 Grade 2507, EN 1.4462, EN 1.4410, UNS S31803, UNS S32205, UNS S32750

6. Super Duplex Steel: A high-alloy steel with exceptional corrosion resistance and strength.

UNS S32750 (1.4410), UNS S32760 (1.4460), UNS S32900 (1.4477), EN 1.4410, EN 1.4460, EN 1.4477, ASTM A182 Grade F61, ASTM A182 Grade F65, ASTM A240 Grade S32750, ASTM A240 Grade S32760

7. Inconel: A nickel-chromium alloy with excellent corrosion resistance and high-temperature properties.

Inconel 600 (UNS N06600), Inconel 625 (UNS N06625), Inconel 718 (UNS N07718), Inconel 800 (UNS N08800), Inconel 800H (UNS N08810), Inconel 800HT (UNS N08811), Inconel 825 (UNS N08825), Inconel 925 (UNS N09925), Inconel 725 (UNS N07725), Inconel 690 (UNS N06690)

8. Monel: A nickel-copper alloy with high strength, corrosion resistance, and resistance to acidic environments.

Monel 400 (UNS N04400), Monel 500 (UNS N05500), Monel K-500 (UNS N05500), Monel 405 (UNS N04405), Monel R-405 (UNS N04405)

9. Hastelloy: A nickel-chromium alloy with excellent corrosion resistance and high-temperature properties.

Hastelloy C-276 (UNS N10276), Hastelloy C-22 (UNS N06022), Hastelloy B-2 (UNS N10665), Hastelloy X (UNS N06002), Hastelloy C-4 (UNS N06455), Hastelloy G-30 (UNS N06030), Hastelloy G-35 (UNS N06035)

10. Titanium: A high-strength, low-density metal with exceptional corrosion resistance and biocompatibility.

Ti-6Al-4V (UNS R56400), Ti-5Al-2.5Sn (UNS R54520), Ti-6Al-7Nb (UNS R56700), Ti-3Al-2.5V (UNS R56320), CP-Ti (Commercially Pure Titanium, UNS R50400), Ti-Pd (Titanium-Palladium, UNS R52400), Ti-10V-2Fe-3Al (UNS R58020).

There are several types of clamps, We manufactur:

1. Pipe clamps: Used to secure pipes and tubes in place.

2. Hose clamps: Used to connect and secure hoses.

3. Cable clamps: Used to manage and secure cables.

4. Tube clamps: Used to secure tubes and pipes in place.

5. U-bolts: Used to secure pipes, tubes, and other cylindrical objects.

6. C-clamps: Used for general-purpose clamping.

7. Bar clamps: Used for clamping and holding objects in place.

8. Spring clamps: Used for clamping and holding objects in place.

9. G-clamps: Used for clamping and holding objects in place.

10. F-clamps: Used for clamping and holding objects in place.

11. Web clamps: Used for clamping and securing webbing and straps.

12. Welding clamps: Used to hold objects in place during welding.

13. Brazing clamps: Used to hold objects in place during brazing.

14. Heat clamps: Used to apply heat to a specific area.

15. Vacuum clamps: Used to secure objects in place in vacuum environments.

There are several types of repair clamps, We manufacture:

1. Pipe repair clamps: Used to repair leaks or damages in pipes.

2. Hose repair clamps: Used to repair leaks or damages in hoses.

3. Tube repair clamps: Used to repair leaks or damages in tubes.

4. O-ring clamps: Used to replace or repair O-rings in pipes, hoses, or tubes.

5. Gasket clamps: Used to replace or repair gaskets in pipes, hoses, or tubes.

6. Split tee clamps: Used to repair or replace split tees in pipes or hoses.

7. Full circle clamps: Used to repair or replace full circle clamps in pipes or hoses.

8. Worm gear clamps: Used to repair or replace worm gear clamps in pipes or hoses.

9. Bolt-on clamps: Used to repair or replace bolt-on clamps in pipes or hoses.

10. Stainless steel clamps: Used to repair or replace stainless steel clamps in pipes or hoses.

11. Emergency repair clamps: Used for emergency repairs in pipes, hoses, or tubes.

12. Permanent repair clamps: Used for permanent repairs in pipes, hoses, or tubes.

13. Temporary repair clamps: Used for temporary repairs in pipes, hoses, or tubes.

14. Hydraulic repair clamps: Used for hydraulic repairs in pipes, hoses, or tubes.

15. Pneumatic repair clamps: Used for pneumatic repairs in pipes, hoses, or tubes.

Pipe Repair Split Clamps are commonly used in various industries, including:

1. Oil and gas

2. Chemical processing

3. Power generation

4. Water treatment

5. Construction

When selecting a Pipe Repair Split Clamp, consider factors such as:

1. Pipe size and type

2. Damage location and extent

3. Fluid type and pressure

4. Temperature range

5. Corrosion resistance

6. Ease of installation.

Pipe repair and support clamps manufactured from forging, plate for seamless and welded pipes, fittings, flanges with the die bending and CNC, VMC and lathe machined and we are one of the brand manufacturer, supplier, distributors and exporters.

Documents:

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Commercial Invoice, including HS Code

- Packing List including the number of boxes, net weight, gross weight, Marks, and Numbers

- Fumigation Certificates

- Letter of guarantee

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

- Raw Material Test Reports

- Heat Treatment Charts

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- MATERIAL TRACEABILITY RECORDS

- Quality Assurance Plan (QAP)

- NABL-approved Laboratory Test Reports.

- HSN code Certificate

Testings (Destructive, Non Destructive):

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- Ultra Sonic Test (UT)

- Eddy Current Testing

- Impact Test

- Bend Test

We Manufacture, Export and supply to many Countries as follows :

- ASIA – India, China Thailand, Singapore, Sri Lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein.

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary, Belarus, Bulgaria, Slovakia, Moldova.

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands.

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See.

- South America – Argentina, Chile, Brazil, Colombia, Paraguay.

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger, Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena.

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara.

- Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland.

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.