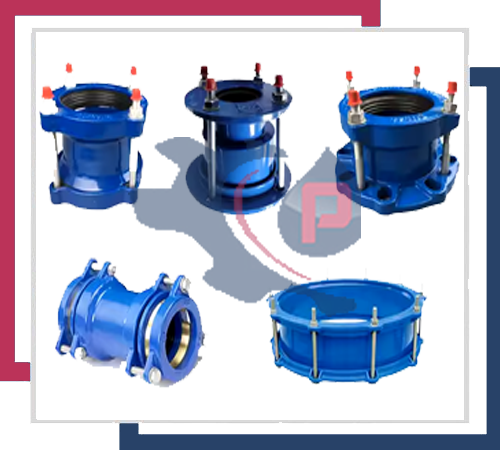

Pipe Sleeve Coupling

PetroSan’s passion is Producing high-quality pipe sleeve coupling or sleeve pipe coupling for long-term pipeline repairs. For the past ten years, we have been a dependable partner in the production of sleeves for the authorized market since we comprehend the needs and applications of our clients.

The most recent addition to Total Piping Solutions’ line of high-performing, value-added, and inventive products is PetroSan pipe sleeve coupling, sleeve coupling, coupling sleeve for pipe repair, pipe repair sleeve coupling, pipe leak stop coupling, sleeve for pipe repair, pipe fix sleeve coupling, two pipe joint coupling, pipe end coupling, pipe joint sleeve coupling.

As a reputable organization in the field, we have a strong commitment to producing and distributing the highest caliber of Sleeve Pipe Coupling. The suggested coupler facilitates the merging of two pipes. Because of its longevity, flexibility, and resistance to leaks, this type of coupler is perfect for ash transportation pipelines. Constructed using advanced technology from premium cast steel, it is flawlessly finished and covered in metallic paint to prevent rust. Additionally, the Sleeve Pipe Coupling is readily available from us at rates that are reasonable for the market.

A sleeve pipe coupling is a type of pipe fitting that connects two pipes together using a sleeve or a tube that wraps around the pipes. It is a mechanical connection that transfers loads and stresses between the pipes, allowing them to be joined together without welding or threading.

Sleeve pipe couplings consist of:

1. A sleeve or tube that wraps around the pipes

2. A locking mechanism (e.g., bolts, nuts, or clamps) that secures the sleeve in place

3. Gaskets or seals to prevent leakage

Types of sleeve pipe couplings include:

1. Standard sleeve couplings

2. High-pressure sleeve couplings

3. Flexible sleeve couplings

4. Rigid sleeve couplings

5. Adjustable sleeve couplings

6. Split sleeve couplings

Sleeve pipe couplings are used in various applications, including:

1. Oil and gas pipelines

2. Water and wastewater treatment

3. Chemical processing

4. Power generation

5. HVAC systems

6. Industrial piping systems

The benefits of sleeve pipe couplings include:

1. Easy installation and maintenance

2. No welding or threading required

3. Flexibility and adjustability

4. High strength and durability

5. Resistance to corrosion and abrasion

6. Leak-tight connections

When selecting a sleeve pipe coupling, consider factors such as:

1. Pipe size and material

2. Pressure and temperature ratings

3. Corrosion resistance

4. Flexibility and adjustability requirements

5. Ease of installation and maintenance

6. Cost and availability

Documents:

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Commercial Invoice, including HS Code

- Packing List including the number of boxes, net weight, gross weight, Marks, and Numbers

- Fumigation Certificates

- Letter of guarantee

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

- Raw Material Test Reports

- Heat Treatment Charts

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- MATERIAL TRACEABILITY RECORDS

- Quality Assurance Plan (QAP)

- NABL-approved Laboratory Test Reports.

- HSN code Certificate

Testings (Destructive, Non Destructive):

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- Ultra Sonic Test (UT)

- Eddy Current Testing

- Impact Test

- Bend Test

PetroSan Product Quick Links :

Cold/Hot Tapping Fittings, Dismantling joint Clamp, Flange Adapter, Flange repair ring clamp, Line Stop hot tapping fittings, PetroSan Pipe Sleeve, Petrosan Sleeve + Clamp, Pipe End mechanical Coupling, Pipe Reinforcing Split Sleeve, Pipe Riser Clamp, Pipe Sleeve Coupling, Split Sleeve Pipe Repair Clamp, Stainless Steel Clamp, Tube insert’s ferrule (Alloy 693), Tube insert’s or Ferrule (Alloy 601), Tube insert’s or Ferrule (Alloy 602ca), Tube inserts – ferrule, type a Reinforcing Sleeve, type b Reinforcing Sleeve, Pipe Sleeve Coupling, Pipe Riser Clamp, Flange Adapter, Dismantling Joint Clamp, Bolted Split Sleeve, ASTM A516 GR. 70 Pipe Repair Clamp

We Manufacture, Export and supply to many Countries as follows :

- ASIA – India, China Thailand, Singapore, Sri Lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein.

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary, Belarus, Bulgaria, Slovakia, Moldova.

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands.

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See.

- South America – Argentina, Chile, Brazil, Colombia, Paraguay.

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger, Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena.

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara.

- Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland.

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.