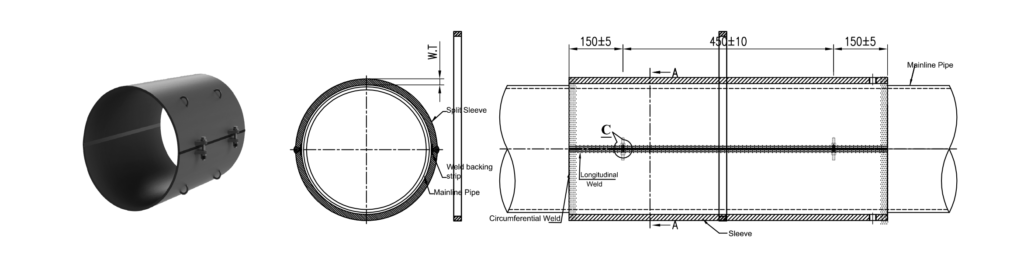

Type A Reinforcing Sleeve

PetroSan’s passion is Producing high-quality type A reinforcing sleeve or type A Full Encirclement Pipe Sleeve for long-term pipeline repairs. For the past ten years, we have been a dependable partner in the production of sleeves for the authorized market since we comprehend the needs and applications of our clients. All throughout the world.

Petrosan Oilfiled Engg. Co. is the most recent addition to Total Piping Solutions’ line of high-performing, value-added, and inventive products is pipe support, type A reinforcing sleeve or type A Full Encirclement Pipe Sleeve, pipe sleeve, pipe support external sleeve, Full Encirclement Pipe Sleeve, Type A Sleeve, Full Encirclement Steel Sleeve, Type A Half Pipe Sleeve, Type A sleeve for pipeline, Type A Steel Reinforced Sleeves, Type A Steel Repair Sleeves, Type A Weld Sleeves, Type A Reinforcement sleeve, Type A pipe weld sleeve, Type A two half sleeve, Type A split sleeve, Type A split welded sleeve.

One kind of pipe fitting used to strengthen and fix pipelines is a TYPE A pipe reinforcing sleeve. It is a cylinder sleeve that is put around a weak or broken pipe segment to provide it more support and strength. Usually composed of carbon steel, stainless steel, or duplex steel, the sleeve is constructed to match the original pipe’s diameter and thickness.

Pipe reinforcing sleeves are used to:

1. Repair cracks, corrosion, dents, gouges, and leaks in pipelines

2. Reinforce weakened areas of pipe due to corrosion, erosion, or mechanical damage

3. Extend the lifespan of pipelines

4. Prevent further damage or propagation of defects

5. Restore the original strength and integrity of the pipeline

Types of pipe reinforcing sleeves include:

1. Standard sleeves

2. High-strength sleeves

3. Corrosion-resistant sleeves

4. Insulated sleeves

5. Flanged sleeves

Installation methods include:

1. Welding

2. Bolting

3. Clamping

4. Application of adhesives

Industry applications include:

1. Oil and gas

2. Chemical processing

3. Power generation

4. Water treatment

5. Construction

Benefits of using pipe reinforcing sleeves include:

1. Cost-effective solution compared to replacing the entire pipeline

2. Quick and easy installation

3. Minimized downtime and disruption to operations

4. Improved safety and reliability

5. Customizable to fit specific pipeline requirements

Installing a pipe reinforcing sleeve typically involves the following steps:

1. Preparation:

– Clean the area around the damaged pipe section

– Remove any debris, corrosion, or old coatings

– Ensure the pipe surface is dry and free of oil or grease

2. Measurement:

– Measure the outer diameter (OD) and length of the damaged pipe section

– Determine the required sleeve size and length

3. Cutting:

– Cut the sleeve to the required length using a saw or cutting tool

4. Application of adhesive (if required):

– Apply a suitable adhesive (e.g., epoxy) to the sleeve and pipe surface

5. Installation:

– Slide the sleeve over the damaged pipe section

– Align the sleeve with the pipe, ensuring even spacing and coverage

6. Securing:

– Use appropriate fastening methods (e.g., welding, bolting, or clamping) to secure the sleeve to the pipe

7. Tightening:

– Tighten all fasteners according to the manufacturer’s recommendations

8. Inspection:

– Visually inspect the installation to ensure proper alignment, coverage, and security

9. Testing (if required):

– Perform pressure testing or other necessary tests to ensure the sleeve is properly installed and functioning correctly

Note: The specific installation procedure may vary depending on the type of sleeve, pipe material, and industry standards. It’s essential to consult the manufacturer’s instructions and follow appropriate safety protocols during installation.

Additionally, consider the following general tips:

– Use proper handling and storage techniques to avoid damaging the sleeve

– Ensure the sleeve is properly aligned and centered on the pipe

– Use appropriate fastening methods and torque values to avoid damaging the pipe or sleeve

– Consider applying a coating or wrap to the sleeve for additional protection

– Document the installation process and maintain records for future reference

Manufacturer and fabricators of Type A pipe repair sleeve.

Manufacturer of Full Encirclement Pipe Sleeve, Manufacturer of Type A Sleeve, Manufacturer of Full Encirclement Steel Sleeve, Manufacturer of Type A Half Pipe Sleeve, Manufacturer of Type A sleeve for pipeline, Manufacturer of Type A Steel Reinforced Sleeves, Manufacturer of Type A Steel Repair Sleeves, Manufacturer of Type A Weld Sleeves, Manufacturer of Type A Reinforcement sleeve, Manufacturer of Type A pipe weld sleeve, Manufacturer of Type A two half sleeve, Manufacturer of Type A split sleeve, Manufacturer of Type A split welded sleeve, Manufacturer of Type A Reinforcing Sleeves for Pipe Repair, Manufacturer of Type A Reinforcing Sleeves for Pipeline Repair, Manufacturer of Type A Reinforcing Sleeves for Pipe Rehabilitation, Manufacturer of Type A Reinforcing Sleeves for Pipe Corrosion Protection, Manufacturer of Type A Reinforcing Sleeves for High-Pressure Pipe Repair.

Petrosan is well known type a Pipe reinforcing sleeve fabricators, type a Pipe repair sleeve fabricators, type a Pipe reinforcement sleeve fabricators, type a Pipe strengthening sleeve fabricators, type a Pipe rehabilitation sleeve fabricators, type a Pipe repair sleeve fabricators, type a Pipe maintenance sleeve fabricators, type a Pipeline repair sleeve fabricators, type a Pipeline maintenance sleeve fabricators, type a Pipe fitting sleeve fabricators, type a Pipe coupling sleeve fabricators, type a Pipe adapter sleeve fabricators, type a Pipe reinforcement sleeve fabricators, type a Pipe repair wrap sleeve fabricators, type a Pipe reinforcement tape sleeve fabricators

Documents:

- Certificate of Origin legalized/attested by Chamber of Commerce or Embassy

- Commercial Invoice, including HS Code

- Packing List including the number of boxes, net weight, gross weight, Marks, and Numbers

- Fumigation Certificates

- Letter of guarantee

- Material Test Certificates as per EN 10204 3.1, EN 10204 3.2

- Test Certificates certifying NACE MR0103, NACE MR0175

- Raw Material Test Reports

- Heat Treatment Charts

- Welding Procedure Specification/Procedure Qualification Record, WPS/PQR

- MATERIAL TRACEABILITY RECORDS

- Quality Assurance Plan (QAP)

- NABL-approved Laboratory Test Reports.

- HSN code Certificate

Testings (Destructive, Non Destructive):

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- Ultra Sonic Test (UT)

- Eddy Current Testing

- Impact Test

- Bend Test

We Manufacture, Export and supply to many Countries as follows :

- ASIA – India, China Thailand, Singapore, Sri Lanka, Bangladesh, South Korea, Indonesia, Philippines, Vietnam, Kazakhstan, Azerbaijan, Turkmenistan.

- Middle East – Kuwait, Dubai, Saudi Arabia, Qatar, Oman, Bahrain, Jordan, Turkey, Iraq, Yemen, Syria, Azerbaijan, United Arab Emirates, Israel.

- Western Europe – Germany, France, Netherlands, Belgium, Austria, Switzerland, Luxembourg, Monaco, Liechtenstein.

- Eastern Europe – Russia, Ukraine, Poland, Romania, Czechia, Hungary, Belarus, Bulgaria, Slovakia, Moldova.

- Northern Europe – United Kingdom, Sweden, Denmark, Finland, Norway, Ireland, Lithuania, Latvia, Estonia, Iceland, Isle of Man, Faeroe Islands.

- Southern Europe – Italy, Spain, Greece, Portugal, Serbia, Croatia, Bosnia and Herzegovina, Albania, North Macedonia, Slovenia, Montenegro, Malta, Andorra, Gibraltar, San Marino, Holy See.

- South America – Argentina, Chile, Brazil, Colombia, Paraguay.

- Western Africa – Nigeria, Ghana, Côte dIvoire, Niger, Burkina Faso, Mali, Senegal, Guinea, Benin, Togo, Sierra Leone, Liberia, Mauritania, Gambia, Guinea-Bissau, Cabo Verde, Saint Helena.

- Northern Africa – Egypt, Sudan, Algeria, Morocco, Tunisia, Libya, Western Sahara.

- Southern Africa – South Africa, Namibia, Botswana, Lesotho, Swaziland.

- Eastern Africa – Ethiopia, Tanzania, Kenya, Uganda, Mozambique, Madagascar, Malawi, Zambia, Zimbabwe, South Sudan, Rwanda, Burundi, Somalia, Eritrea, Mauritius, Djibouti, Réunion, Comoros, Mayotte, Seychelles.